Search This Supplers Products:asphalt mixing plantasphalt mixing plant mobileasphalt Recycling Plantasphalt plant manufacturerstone crusher plant

What is an Asphalt Mixing Plant

time2022/11/30

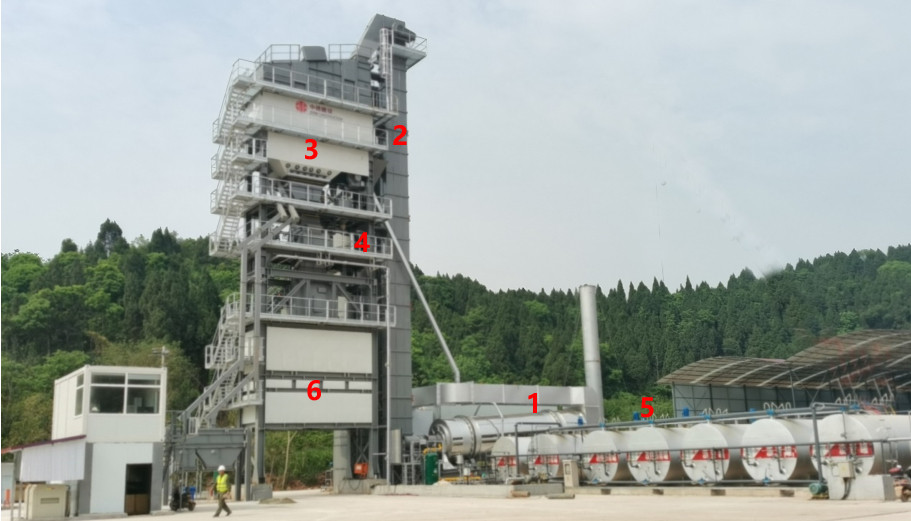

- An asphalt plant, also known as an asphalt mixing plant or hot mix plant, is equipped that can mix aggregate and asphalt to produce an asphalt mixture for road paving.

An asphalt plant, also known as an asphalt mixing plant or hot mix plant, is equipped that can mix aggregate and asphalt to produce an asphalt mixture for road paving. In some cases, it may be necessary to add mineral fillers and additives to the mixing process. The asphalt mixture can be widely used on highways, municipal roads, parking lots, airport expressways, and other road surfaces.

While there are various classification criteria for asphalt equipment, some representative types, such as batch mixing, drum mixing, moving, and recycling, are widely understood and accepted.

Definition

The asphalt mixing plant is a complete set of equipment that produces the final mixture batch by batch. It is characterized by intermittent pauses between batches. Its products are of high-quality thanks to precise weighing systems for aggregates, bitumen, and other admixtures. Because of the mixer, there is a time interval between two mixing batches, so it is also called batch or intermittent.

In an asphalt mixing plant, a mixer with double arms and paddles means that the mixing quality is undoubtedly better compared to a continuous mixing plant because it is mandatory.

Working Process

1. Aggregate is conveyed by belt conveyor from the cold feeder to the rotary drying drum, where moisture is removed.

2. It is then lifted to a set of screens where it is divided into several component sizes and stored in thermally aggregated temporary storage boxes.

3. Then put these aggregates into the weighing hopper correctly in proportion.

4. Introduce it into the blender and mix for the indicated time.

5. Introduce the liquid bitumen at the proper time and then mix the mixture for the required time.

6. The mixer door is opened at the end of the cycle and the finished asphalt mixture is unloaded directly into waiting trucks or special storage bins.

Advantages

Batch blending plants produce finished products of very high quality due to the precise measurement of each batch produced.

The intermittent production process allows them to easily switch back and forth between different mix formats when necessary.

In batch plants, mixers use arms with paddles attached to create forced or physical mixing of ingredients.

In most cases, they come with baghouses. The dust generated in the whole process can be captured, and the surrounding environment will not be polluted too much.

Asphalt plants produce precise small batches of asphalt mix through an iterative process until the project's gross tonnage is manufactured. From the beginning of hot aggregate weighing to the completion of unloading, a whole batch usually takes about 40 to 45 seconds. Depending on the type of material being produced, the mixing time can be increased or decreased, thereby changing the quality of the mix.

Why Choose D&G MACHINERY Asphalt Mixing Plant?

Since D&G Machinery launched the integral recycled asphalt mixing equipment in the market for the first time in 2013, this product has gone through the severe test of the market and accumulated a good reputation. The market position of high-end asphalt mixing equipment suppliers has been further consolidated. After the achievements, D&G Machinery did not satisfy the status quo, always based on technological innovation, and continuously invested in research and development. In 2020, it launched a "deformable" DGX series product to the market.

The DGX series has the advantages of being "one machine with multiple types, combined on demand", adopts the idea of cross-model planning and design, and each functional module is combined according to different modes to realize the conversion of different equipment styles and functions and meet the needs of different production conditions. different requirements. In addition, D&G designers have learned from the opinions of equipment users and optimized product details to make transportation and installation more convenient and use functions more powerful. Once the product series was launched, it was immediately favored by customers in the industry. For more than a year, DGX series products have been installed or are being installed in many provinces in China.

D&G Machinery always pays attention to the road of low-carbon environmental protection and green development. This time, the two sets of equipment "settle down" in the national key development zone at the same time, which marks the full recognition of the customer and the local environmental protection department, and also marks the other precision in the park. The recognition of the manufacturer of the part also marks that the products of D&G Machinery have been recognized by the most stringent environmental assessment standards and have been invested in the construction and development at the national level. With this "recognition" in mind, D&G Machinery will forge ahead and dedicate its own strength to China's equipment manufacturing industry professionally and dedicatedly!

DGX Asphalt Mixing Plant

DGX asphalt mixing plant adopts the idea of cross-model on planning and design, which can realize the conversion of different equipment styles and functions and meet the requirements of different production conditions with each functional module combined according to different modes. For the need of production, which can be assembled according to its type.