Search This Supplers Products:asphalt mixing plantasphalt mixing plant mobileasphalt Recycling Plantasphalt plant manufacturerstone crusher plant

Maintenance of Asphalt Mixing Plant

time2023/03/31

- Whether you're considering buying a new one or looking to improve the efficiency of your existing asphalt mixing plant, this maintenance guide from D&G MACHINERY can help you make an informed decision.

Preparing a quality asphalt mix is not an easy task. It requires the right equipment and quality materials. When it comes to which equipment can help you produce high-quality asphalt mixture, batch asphalt mixing plants are the most popular choice. However, this equipment requires regular maintenance for optimal performance. Whether you're considering buying a new one or looking to improve the efficiency of your existing asphalt mixing plant, this maintenance guide from D&G MACHINERY can help you make an informed decision.

The Importance of Maintaining an Asphalt Mixing Plant

An asphalt mixing plant is one of the essential facilities in construction and road construction. They are primarily used to make asphalt mixture, a key component of roads and other building structures. Therefore, the importance of maintaining an asphalt mixing plant is very high for several reasons:

Maintain Production Capacity

If an asphalt mixing plant is not properly maintained, the equipment can malfunction or shut down, which can lead to reduced production capacity. If the mixing plant cannot operate as planned, it will affect the construction progress, so maintenance is very necessary.

Increase Productivity

By regularly inspecting and maintaining your equipment, you can ensure that they are operating at peak efficiency. Making necessary repairs and replacing parts during maintenance reduces downtime and increases productivity.

Security

Maintenance also ensures that equipment is safe and reliable. If equipment is not maintained, hazardous situations may arise such as machine failure, fire, or explosion. To keep employees safe, regular inspections and maintenance are crucial.

Extend Equipment Life

Excessive wear and damage to equipment can be avoided through regular inspection and maintenance, which prolongs the life of the equipment and reduces repair and replacement costs.

Compliance with Regulatory Requirements

To comply with regulatory requirements, asphalt mixing plants must be regularly inspected and maintained. If not properly maintained, safety and environmental regulations can be violated, which can lead to fines and other severe consequences.

At the end of the day, routine maintenance, if performed correctly, will help your plant continue to run smoothly and profitably. Maintenance is a necessity that you cannot ignore, and proper maintenance starts long before a plant breaks down. Leveraging a strong maintenance culture in your facility will reduce downtime and maximize your profit margins.

The Best Way to Enhance the Performance of Your Asphalt Mixing Plant

Keep the Facility Clean

Dust, dirt, and oil buildup are the leading causes of most equipment failures. It affects the performance of components, causing frequent failures. Therefore, regular maintenance checks are essential to prolonging the life of your equipment. By following regular cleaning and maintenance procedures, your asphalt batch plant will perform optimally and ensure the smooth operation of its components. You can also perform thorough inspections, assessments, and more to improve plant efficiency.

Use the Latest Tools and Techniques

The best way to increase the efficiency of your batch asphalt mixing plant is to invest in cutting-edge automation and maintenance tools. This saves you maintenance costs, prevents downtime, and delivers results faster. Today, advanced asphalt mixing plants are equipped with electrical control panels and control rooms that help you monitor equipment performance, collect data, and improve its performance in the future. Additionally, you can add optional accessories such as bag-type dust collectors, storage silos, and more to meet your specific needs.

Provide Regular Training for Your Staff

Asphalt mixing plants are complex machines that require expert handling. From feeding aggregates into the silo to controlling operations with the control panel, there's a lot you need to do. Providing regular training to your staff can help you improve the overall process and ensure that your staff has the necessary information to perform all tasks proficiently. Taking employee training initiatives will improve employee morale and will also help identify areas for improvement.

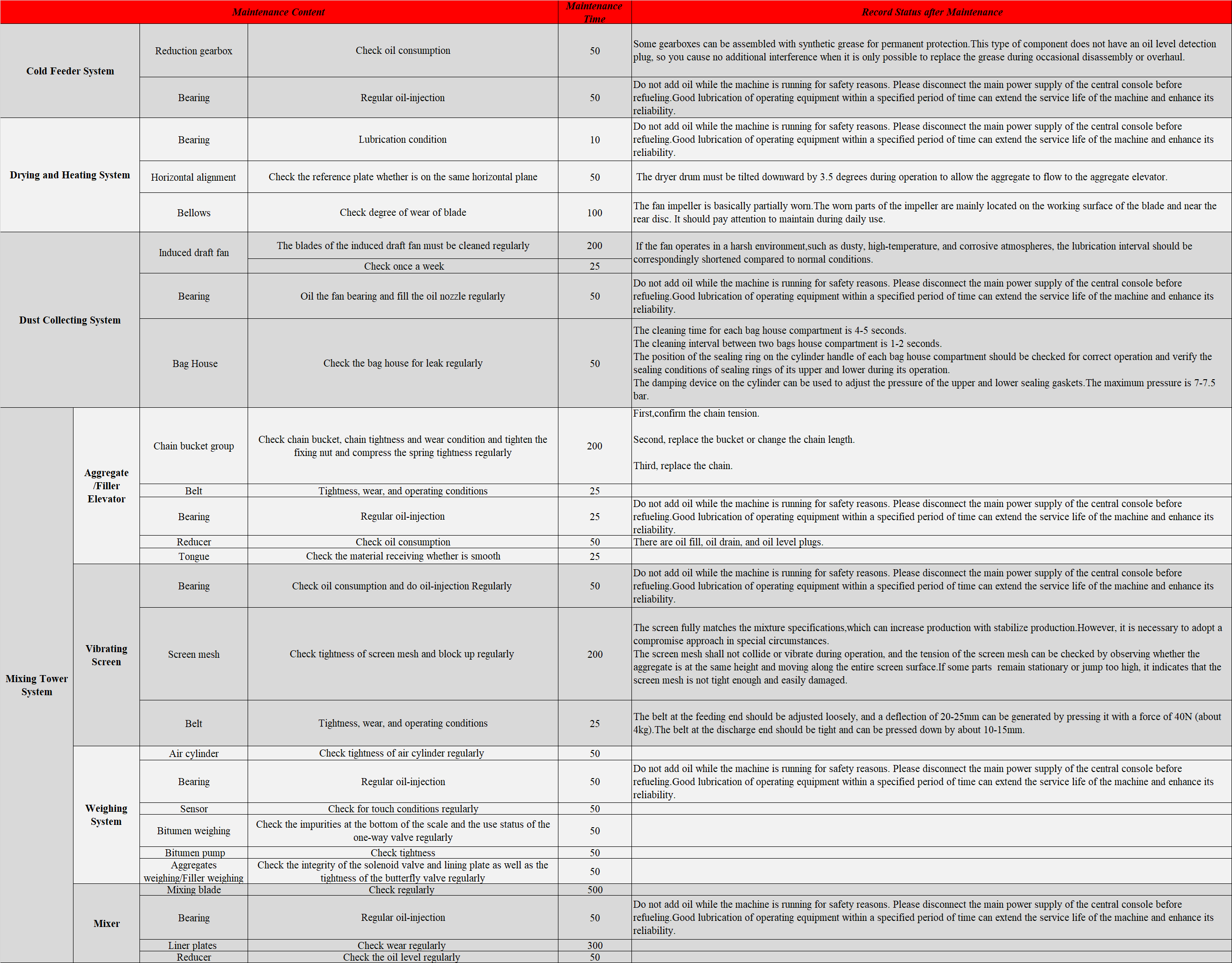

If you want an asphalt mixing plant that is kept in the best condition, you need to carry out holistic and systematic inspection and maintenance of each component of the equipment in order to reduce the failure rate of the equipment and avoid various problems in a later operations. The following is the equipment maintenance schedule carefully organized by D&G MACHINERY for you to help your employees maintain more scientific and clearer maintenance of asphalt mixing plants.

Promote Sustainable Development

While most businesses focus primarily on producing high-quality asphalt, they should also track the waste generated in the process. In addition, recycled materials are also important. Eliminating waste and promoting sustainability can help you save money on energy consumption.

Seek Professional Help

While regular inspections are important, performing a professional audit can also improve the efficiency of your equipment. Audits help review asphalt plant systems, processes, and other components. It will also help you gain a new perspective on how things work and find new ways to extend the life of your system. An audit will also help you identify areas for improvement and make sure things are moving in the right direction.

Buy High-Quality Asphalt Mixing Plant from D&G MACHINERY

D&G MACHINERY is a professional asphalt mixing plant manufacturer. Up to now, D&G MACHINERY has sold nearly 800 sets of asphalt mixing plants. D&G MACHINERY provides a full range of high-end asphalt mixing plants and is a leader in the world. We are also committed to building an information-based, data-based, and intelligent production workshop, which closely integrates information technology and manufacturing technology.

Through advanced productivity, processing, and manufacturing are promoted to be more precise, fast, and efficient, and the processing accuracy and quality of products are improved. With a strong, professional R&D and dedicated service team, D&G MACHINERY is highly recognized by customers as a leading professional manufacturer in the asphalt mixing plant industry and RAP application fields. If you want to buy an asphalt mixing plant, please contact us. 7×24 after-sales service telephone and local service center. We are committed to serving our customers at all times.