Search This Supplers Products:asphalt mixing plantasphalt mixing plant mobileasphalt Recycling Plantasphalt plant manufacturerstone crusher plant

What Are The Different Kinds of Crushers?

time2024/02/21

- There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Each type of crusher for each specific crushing stage is explained in greater detail below.

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is a versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits. Primary crushing involves using a large object as the initial force to break down very large and hard rocks and boulders into smaller pieces before they move onto the secondary stage. Secondary crushing breaks down materials even further before they go to tertiary level, which makes an even finer product that can then be used in various industrial projects. Each type of crusher for each specific crushing stage is explained in greater detail below.

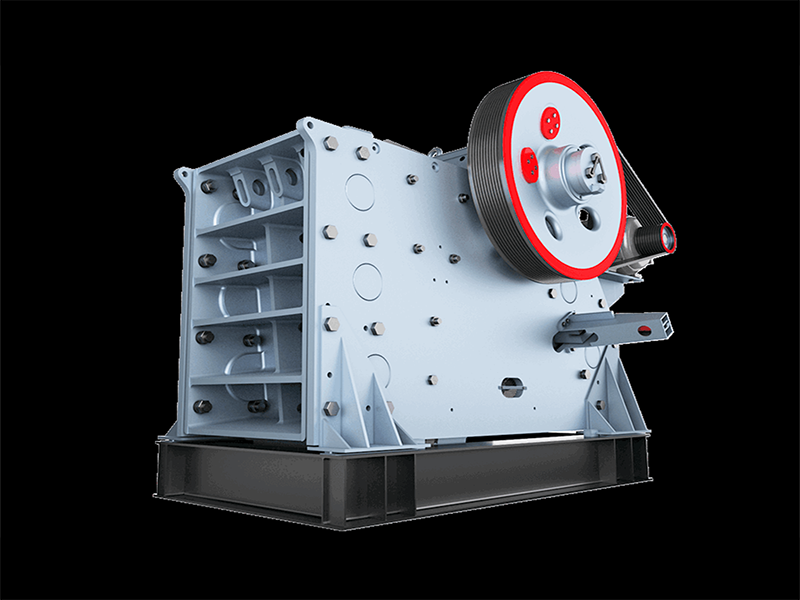

Jaw Crushers

Large amounts of material are fed into the “V-shaped” jaw of this crusher and are reduced using compressive force. One side of the V remains stationary while the other side of the V swings against it. The material is forced from the wide opening of the V to the narrowest point of the V creating a crushing motion. Jaw crushers are large-scale, heavy-duty machinery typically constructed with cast iron and/or steel. Often considered a basic machine, jaw crushers have their place in the industry. They are often used to reduce rock into non-uniformed gravel.

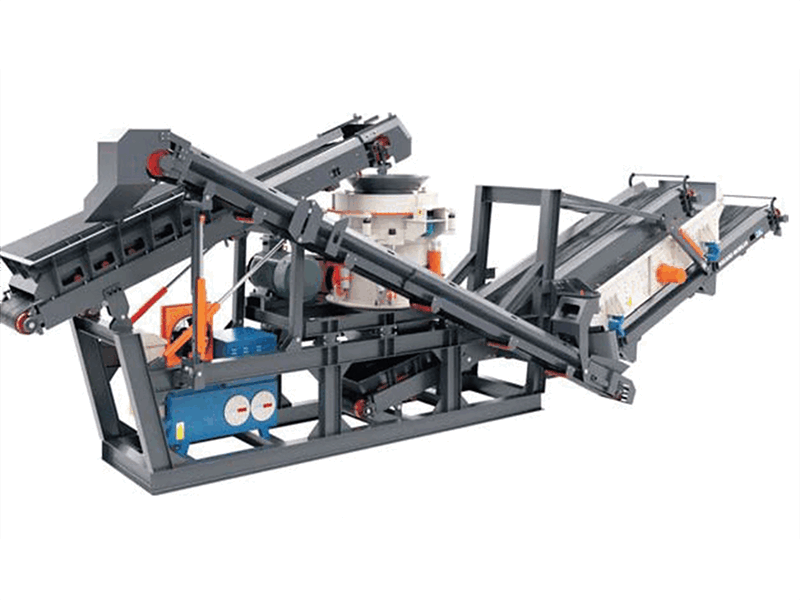

Cone Crushers

Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force. The crushed material is first broken down at the top of the cone where they then fall down into a lower part of the cone that is more narrow. At this point the cone crusher crushes the material again into an even smaller size. This continues until the material is small enough to fall out of the bottom opening. Material from a cone crusher can be used for lots of different projects including road base on construction projects, asphalt pavement resurfacing, or in gravel pits for road construction. Cone crushers are suitable for medium-hard and hard materials - like virgin rock from quarries.

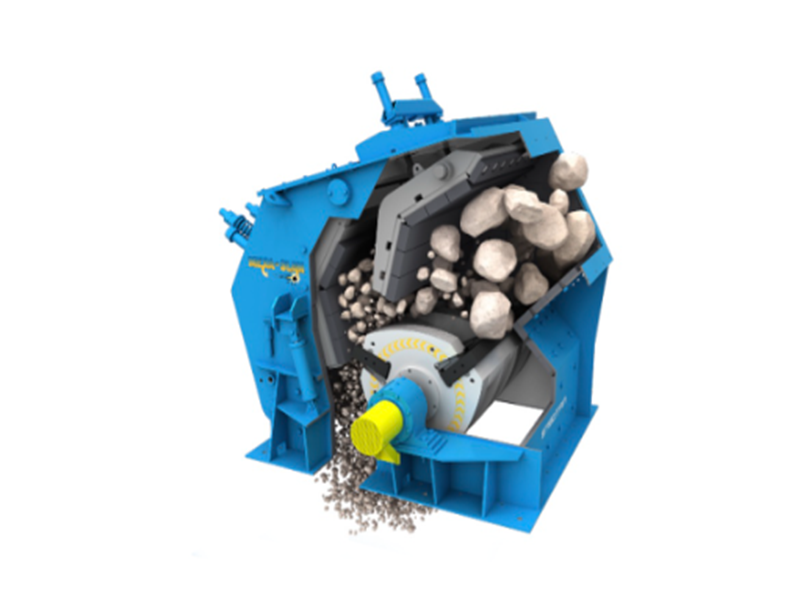

Hammer Mills and Impact Crushers

One of the most versatile crushers available, hammer mills and impactors can be primary, secondary, and tertiary crushers. Hammer mill crushers use continuous hammer blows to shatter and disintegrate material. They are typically horizontal rotating in an enclosed cylinder casing. The hammers are attached to a disk and swing with centrifugal force against the casing. Material is fed into the top and crushed the falls through the hole at the bottom. You will find hammer mills being used in industries like agriculture, medical, energy, and beyond. They provide some of the highest-efficiency outputs available, are portable, and can handle almost any material.

Impact crushers have a very similar working principle except instead of the rotating parts hitting the material like a hammer, they instead throw the material against an impact plate which breaks it down. They also come in horizontal or vertical shaft configurations depending on the desired output.

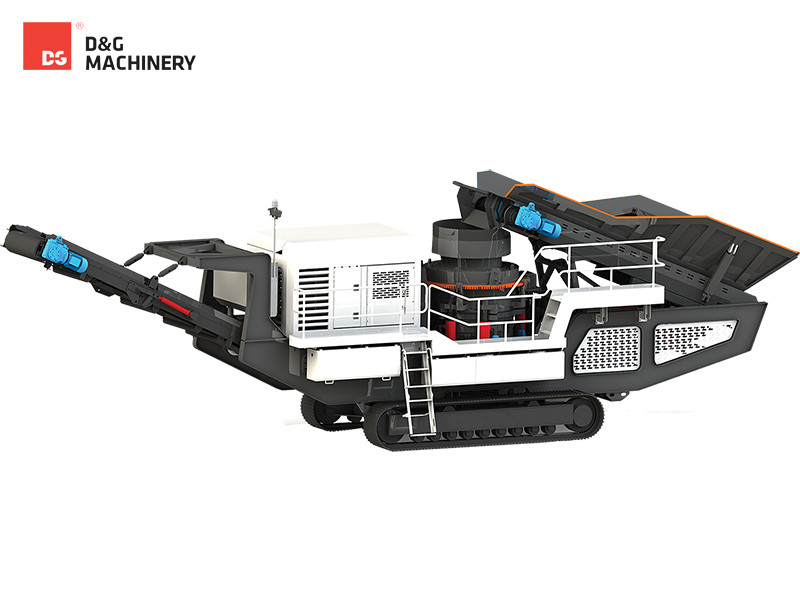

D&G Machinery's crusher products are widely used in domestic and foreign highway construction and commercial mixing enterprises for sand and gravel material needs. Please feel free to contact us directly if you have any needs.