Search This Supplers Products:asphalt mixing plantasphalt mixing plant mobileasphalt Recycling Plantasphalt plant manufacturerstone crusher plant

RAP Asphalt Crusher & Screener

- group name

- RAP Asphalt Crusher & Screener

- Min Order

- 1 piece

- brand name

- D&G Asphalt Plant Manufacturer

- model

- RCS150

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CIF

- Acceptable payment methods

- T/T, L/C, D/P D/A, Cash

- update time

- Thu, 19 Feb 2026 21:37:03 GMT

Paramtents

Rated capacity 150t/h

Moisture content ≤ 3 %

RAP cold feeder CF112

Feeding belt conveyer 200 t/h

Magnetic separator RCYE-8

Primary vibrating screen 15kW

Packging & Delivery

-

Min Order1 piece

Briefing

RCS100-150 RAP Crushing Machine - Capacity: 100-150t/h. Efficient crushing for high-quality output with innovative solution!

Detailed

RAP Asphalt Crusher & Screener

RAP asphalt crusher& screener machine adopts fixed and modular design, flexible matching, convenient installation and quick relocation. It is suitable for the working conditions of asphalt mixing plant.

According to the characteristics of pavement recycled milling materials, the low-speed flexible crushing technology is adopted to better retain the original gradation ratio. The control system is highly efficient and automatic, and the recycled materials are loaded by the loader, which can be operated by one person during operation

Product Features:

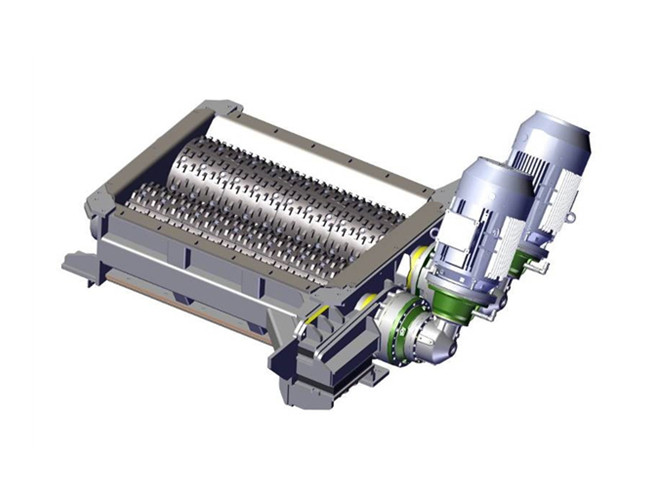

1. Retains the Characteristics of Tooth Roller Asphalt Crushing

It retains the characteristics of tooth roller crushing, and performs shearing, squeezing and bending on the pavement recycled materials, which reduces the impact on the recycled materials compared with jaw breaking and impact breaking, that is, reduces dust emission, and the equipment runs smoothly. Carrying out a crushing effect similar to "kneading" on the recycled materials is to reduce the crushing of large-particle materials. Breaking and squeezing of recycled materials reduces the generation of fine materials, which is also conducive to retaining the original RAP grade ratio.

2.Adopts the Differentiated Arrangement of Crushing Tooth Rollers

It adopts the differentiated arrangement of crushing tooth rollers, which increases the meshing area of shredding teeth compared with ordinary tooth rollers, so that the maximum crushing particle size of the crusher reaches 80mm, and the crushing efficiency is improved.

3. Adopts the Low-speed Flexible Crushing Mode

The low-speed flexible crushing mode is adopted, and the crushing as low as 20 rpm enhances the "kneading" effect of the crushing tooth roller on the material and further reduces the impact on the recycled materials, closer to the concept of flexible crushing, and produces less fine crushed materials.

Main Components :

1.RAP Cold Feeder:

▶ Feed hopper:12 m3

▶ Loading width:3.5m

▶ Loading height:4.1m

▶ Blanking vibration motor power:0.37kW

▶ Power of blanking belt conveyor:3kW

2.Feeding Belt Conveyor:

▶ Belt Width:800mm

▶ Conveying length:17m

▶ Output capacity:200 t/h

▶ Motor power:7.5 kW

3.Tooth-roller Shredder:

▶ Feed particle size:≤80mm

▶ Discharge particle size:≤25mm

▶ Motor power:44kW(22kW×2)

▶ Rated capacity:80t/h

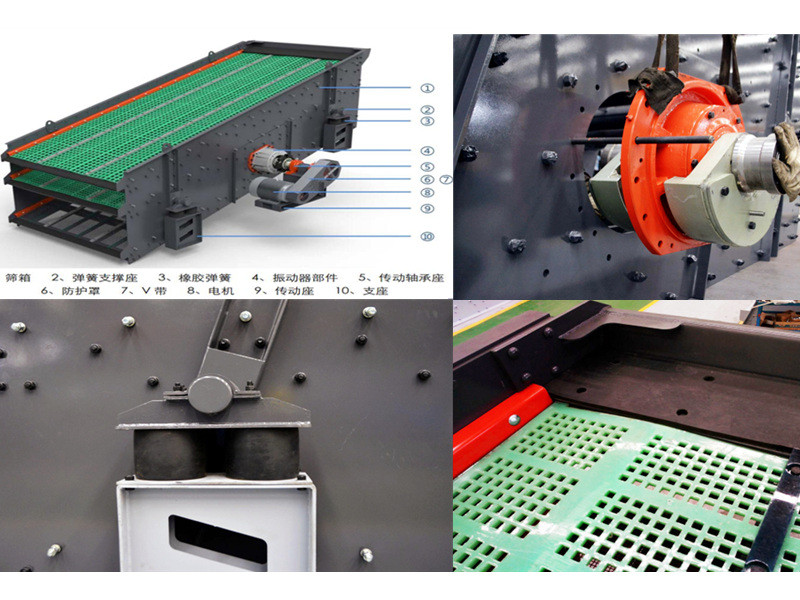

4.Primary Vibrating Screen:

▶ Dimensions:4797×3490×2853

▶ Screen mesh size:16mm/35mm

▶ Screening area:8.1 ㎡×2

▶ Double amplitude:7~12mm

▶ Screening capacity:150t/h

▶ Motor power:15 kW

5.Magnetic Separator:

▶ Permanent Magnetic Self-Unloading Separator RCYE-8

▶ Belt width:800mm

▶ Motor Power:2.2 kW

Product Parameters

|

Model

|

RCS150

|

Aggregate

|

RAP milling material (≤35mm 60%,Maximum particle size

|

|

Capacity

|

150t/h

|

Moisture content

|

≤ 3 %

|

|

Configuration Parameters

|

|||

|

RAP Cold feeder |

CF112

|

12m³

|

3.37kW

|

|

Feeding belt conveyer

|

B800×17m

|

200 t/h

|

7.5kW

|

|

Magnetic Separator

|

RCYE-8

|

Magnetic Separator, self-unloading

|

2.2kW

|

|

Tooth-roller Shredder

|

CTR1200

|

80 t/h

|

2×22kW

|

|

Primary vibrating screen

|

35mm,16mm screen mesh Screening area 2×8.1㎡ |

150 t/h

|

15kW

|

|

Return belt conveyor A

|

B500×6m

|

100 t/h

|

3kW

|

|

Return belt conveyor B

|

B500×11m

|

100 t/h

|

3kW

|

|

Discharge belt conveyor A

|

B500×11m

|

100 t/h

|

4kW

|

|

Discharge belt conveyor B

|

B500×11m

|

100 t/h

|

4kW

|

|

Secondary vibrating screen

|

8mm screen mesh

|

50 t/h

|

2×3.7kW(Optional)

|

|

Discharge belt conveyor C

|

B500×11m

|

100 t/h

|

3kW(Optional)

|

|

Discharge belt conveyor D

|

B500×11m

|

100 t/h

|

3kW(Optional)

|